Fiberglass geogrid: the “invisible guardian” in green infrastructure

Today, as the concept of environmental protection is deeply rooted in people's hearts, fiberglass geogrid, as a high-performance geosynthetics, is becoming a popular choice in the fields of road construction, water conservancy protection, ecological restoration, etc. with its unique environmental advantages and engineering value. This innovative material based on glass fiber not only solves many pain points of traditional geotechnical materials, but also injects new momentum into sustainable development with its green attributes throughout the life cycle.

1. Environmental protection gene: green closed loop from raw materials to recycling

Natural inorganic materialThe main component of fiberglass geogrid is silicon oxide, which is derived from natural siliceous raw materials. No chemical additives are required during the production process, which reduces the risk of pollution from the source. Its inorganic material characteristics make it stable in corrosive environments such as acids, alkalis and salts, avoiding the problem of microplastic pollution caused by material aging.

Recyclable designAfter the product's service life ends, it can be 100% recycled and reused through a crushing and melting process. In the Nanchang Old Road Reconstruction Project, recycled fiberglass gratings were used for temporary road paving after secondary processing, verifying the feasibility of its closed-loop circulation.

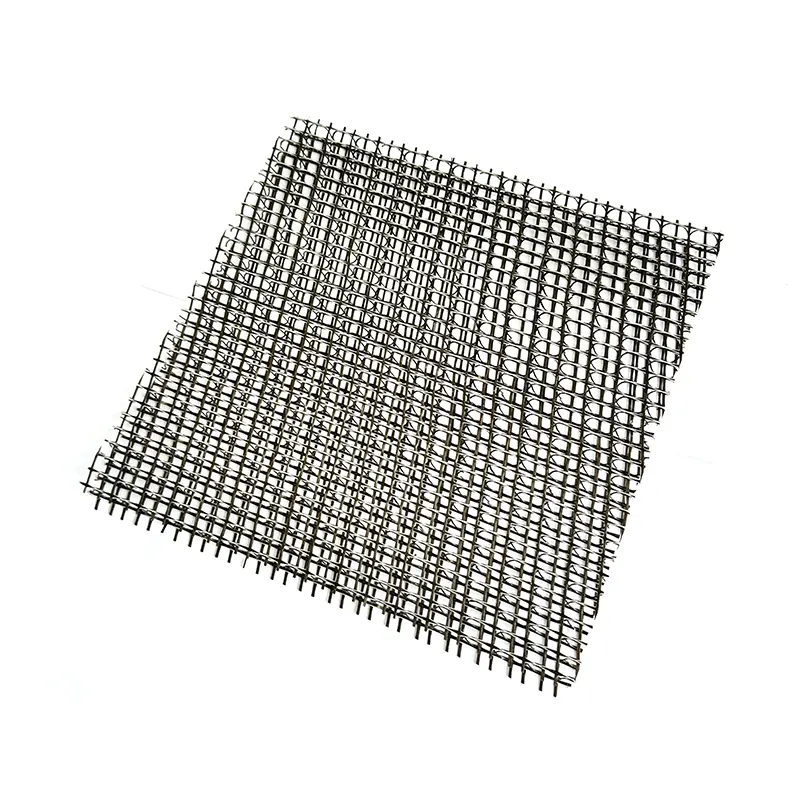

Low-carbon production processUsing internationally advanced warp knitting technology, the energy consumption of traditional metal grating production is reduced by 40%. Taking Taishan Fiberglass as an example, its intelligent production line reduces the carbon emissions per unit product by 25% compared with the industry average through the waste heat recovery system.

II. Performance breakthrough: Beyond traditional engineering value

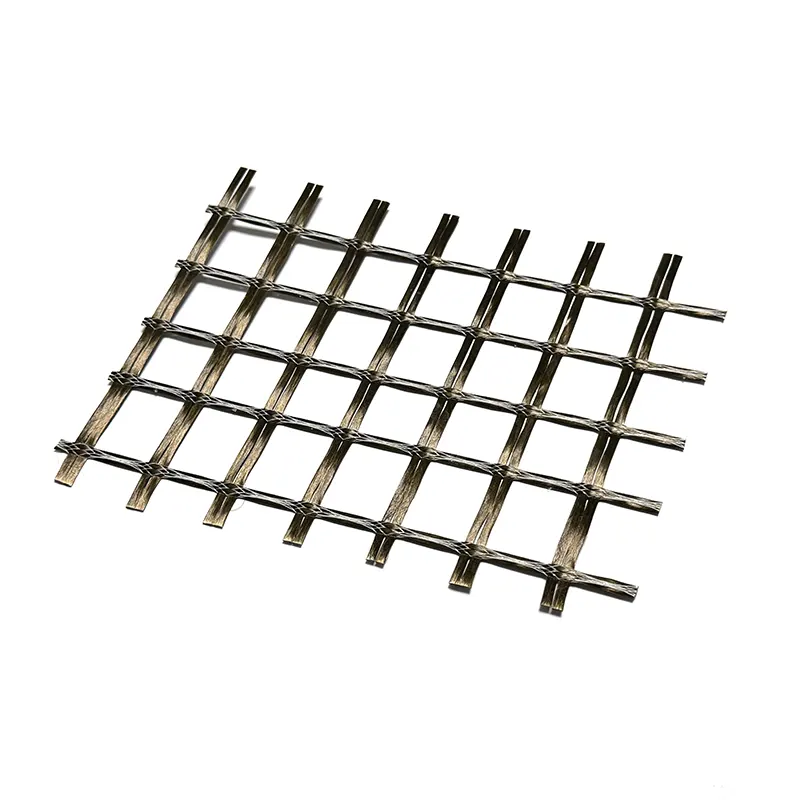

Deformation resistanceThe bidirectional tensile strength of warp and weft can reach 100kN/m, and the elongation at break is less than 3%. In the application of Shanghai-Nanjing Expressway, the incidence of reflective cracks was successfully reduced by 82%. Its mesh structure forms a mechanical interlock with asphalt aggregate, which increases the road surface bearing capacity by more than 3 times.

Adaptability to extreme environmentsMaintains stable performance in the temperature range of -40℃ to 180℃. In the test section of the permafrost zone of the Qinghai-Tibet Plateau, it has withstood the test of an annual temperature difference of 70℃, and the roadbed settlement is controlled within 15mm/20m, which is much better than the traditional gravel cushion solution.

Intelligent compatibilityThe modified asphalt layer coated on the surface is 98% compatible with the asphalt mixture. In the reconstruction and expansion of the Beijing-Shanghai Expressway, the grid and the road surface are integrated, and traffic can be opened 72 hours after construction, which shortens the construction period by 50% compared with the traditional process.