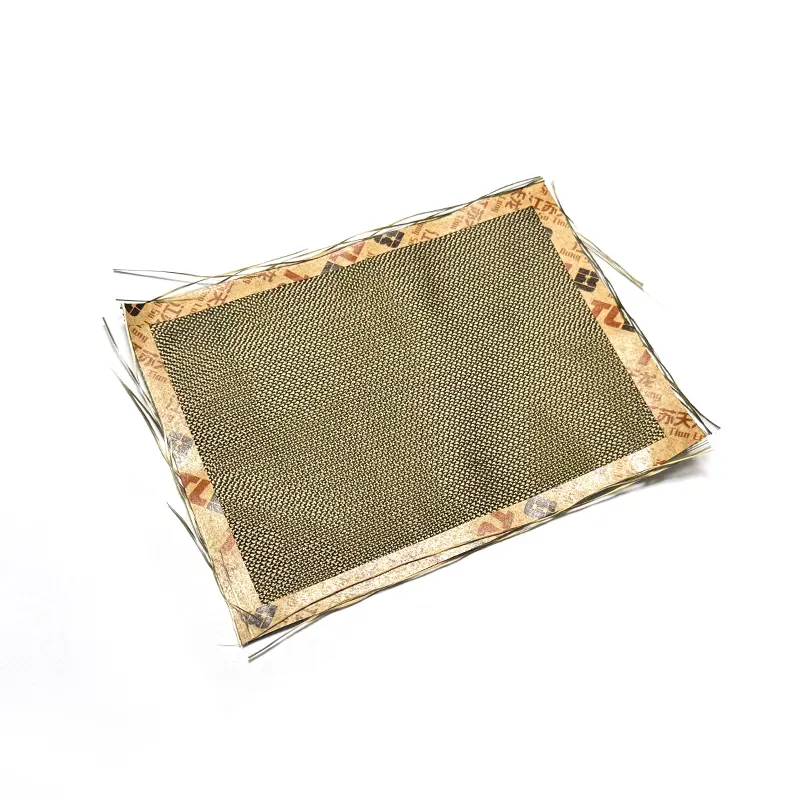

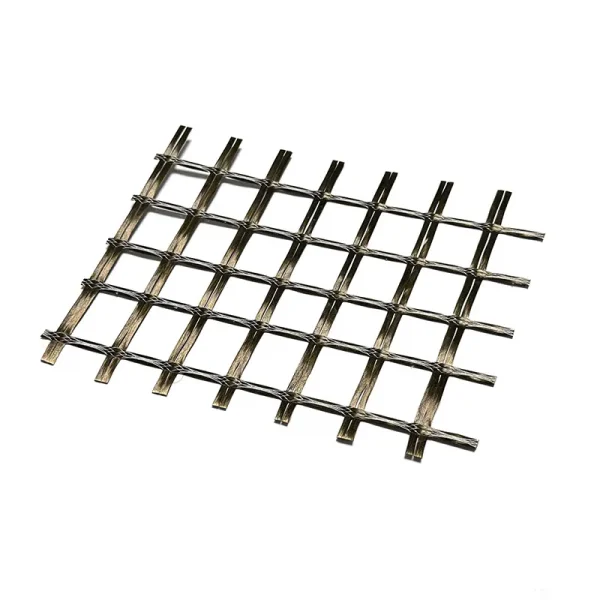

Basalt Uni-Directional Cloth

Basalt uni-directional cloth is woven by basalt twistless roving througha special process. lts monofilament diameter is between 11~13 μ m, unifommlycoated with polyester and epoxy resin together with coupling agent. Theproduct has lots of advantage such as high strength and flexility, convenientfor construction, corrosion resistance, etc. lts overall properties is even betterthan that of carbon fiber and more cost-effective.

- Phone:+86-15061746769

- E-mail:jingguang1220@gmail.com