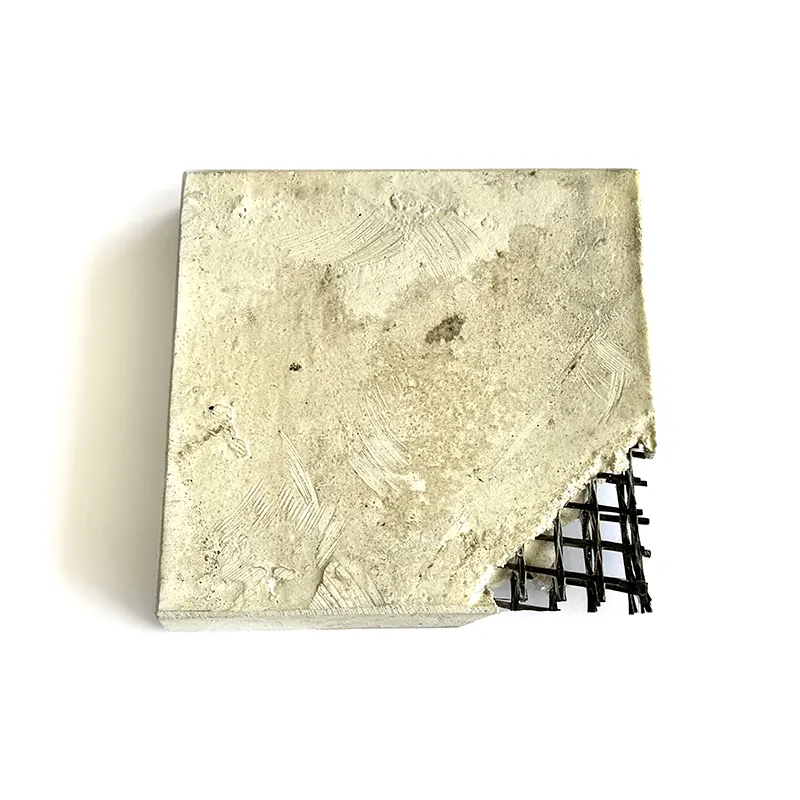

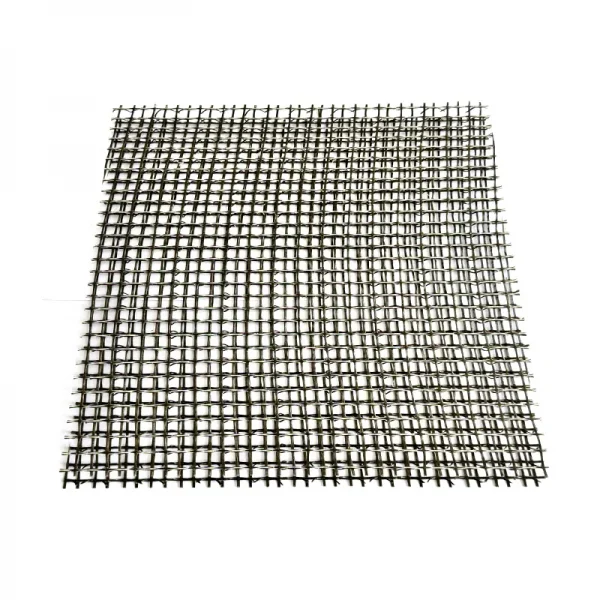

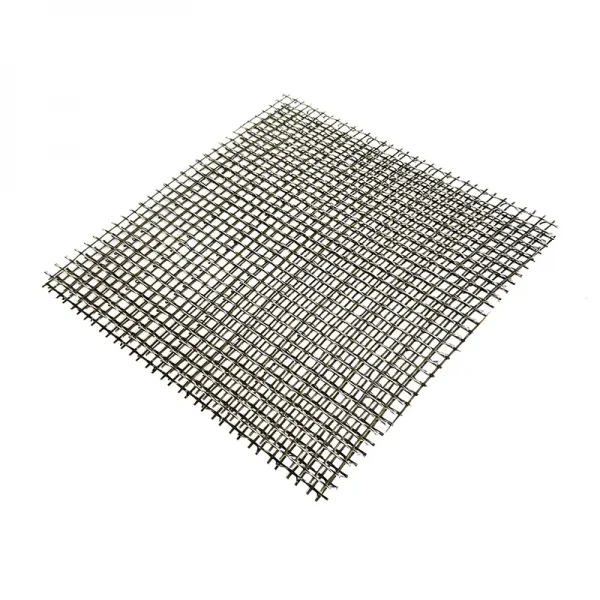

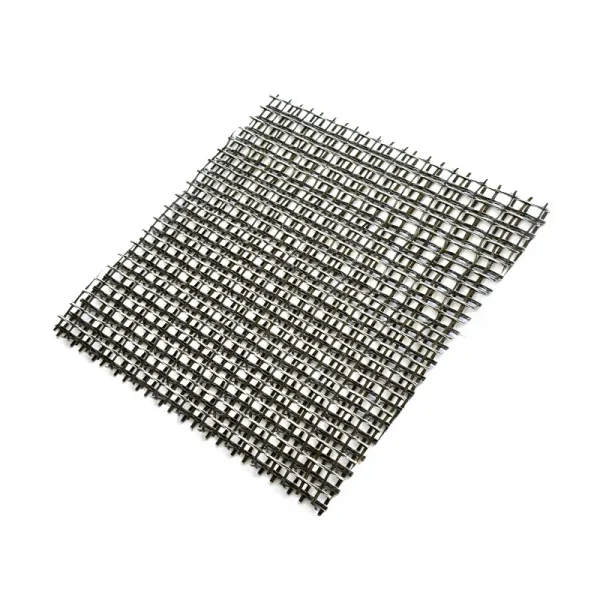

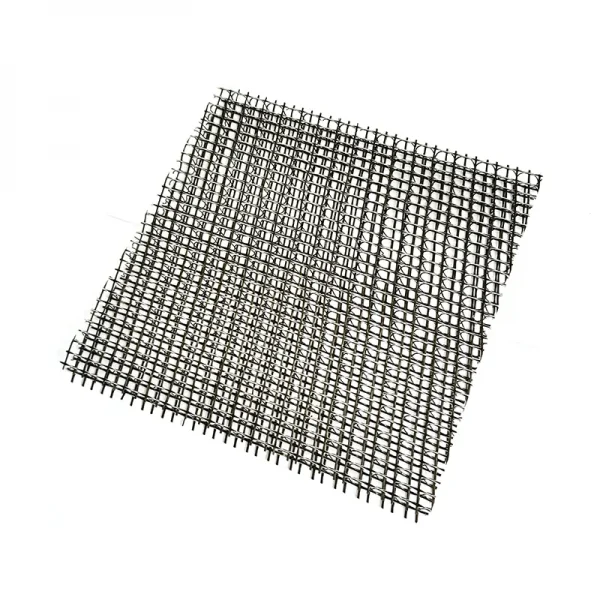

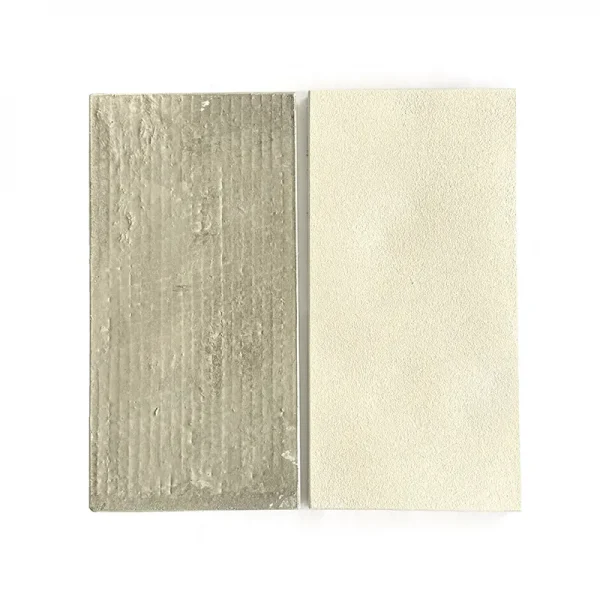

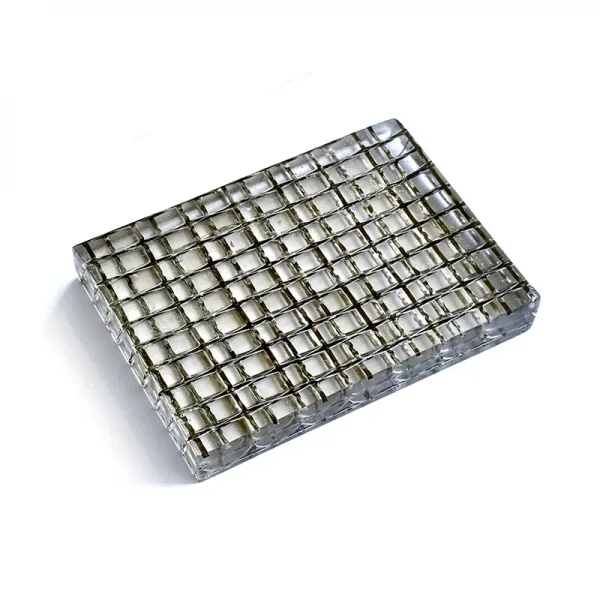

Basalt Microtruss

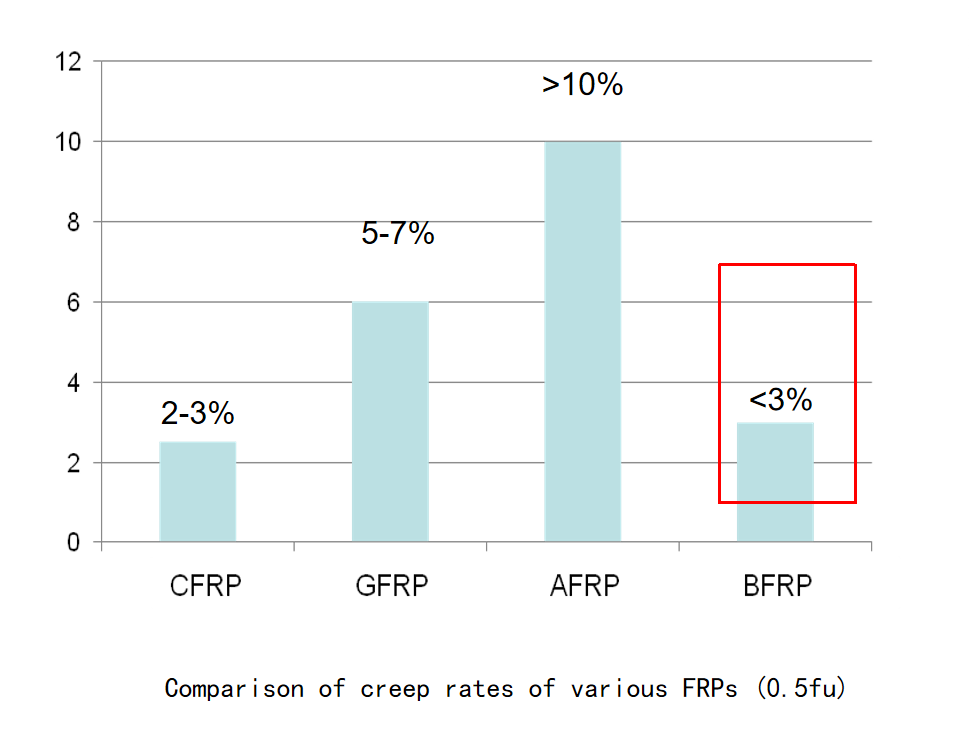

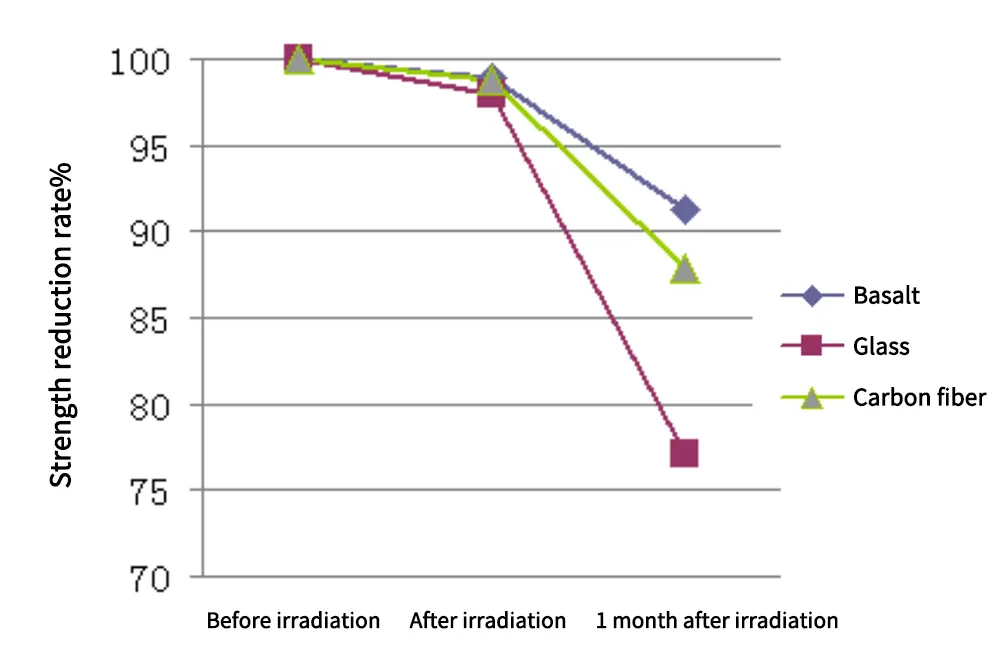

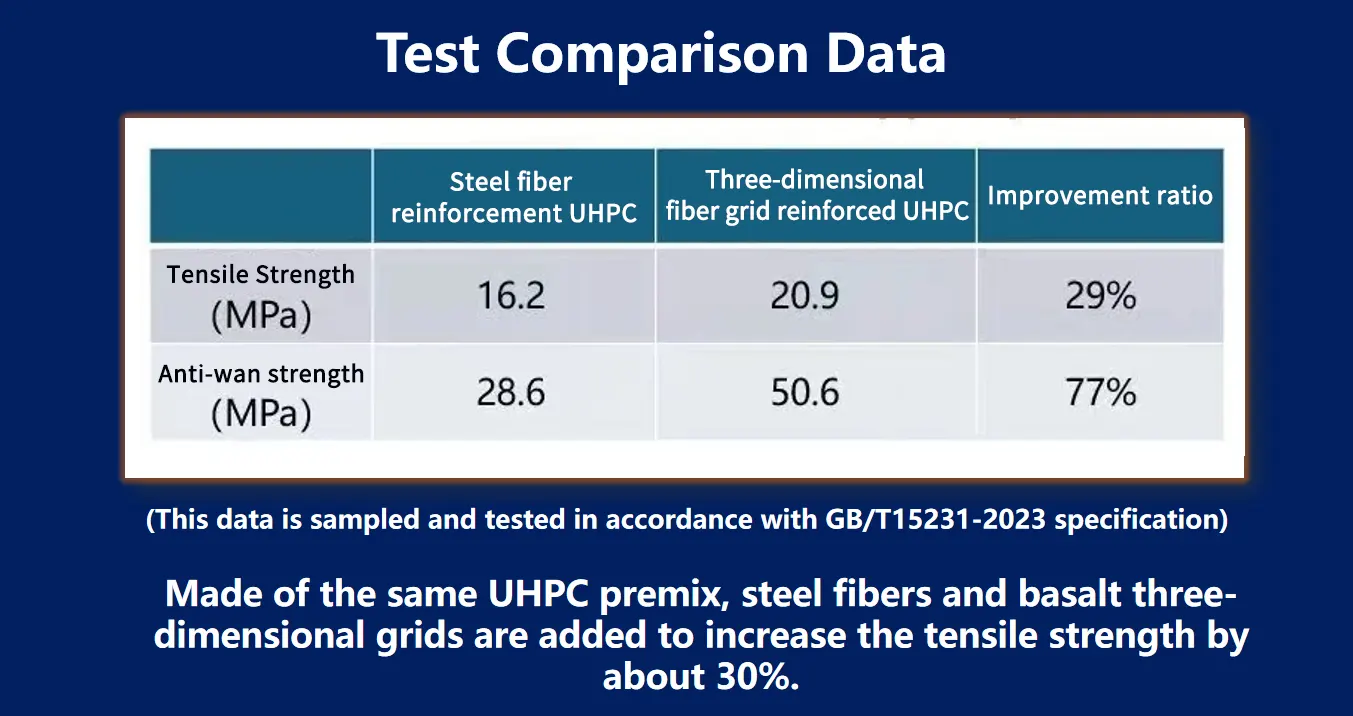

Also known as “basalt three-dimensional grid”, it is a three-dimensional braided fabric with a hollow structure made of basalt fibers. The upper and lower layers are connected by vertical connecting fibers in an “Ω” shape. The structural form is similar to a truss and is suitable for use as a reinforcement in cement components. According to tests, it can greatly improve the mechanical properties of cement products. At the same time, its alkali resistance retention rate can reach 88%.

- Phone:+86-15061746769

- E-mail:jingguang1220@gmail.com